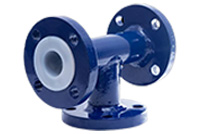

Industrial tees combine or divide the flow of liquids in pipe systems. A PTFE / FEP / PFA Lined Reducing Tee is a specialized type of Tee lined with corrosion-resistant materials to support environments with high temperature and pressure. These Tees are used in industrial processes where there is a need for transporting chemicals and solvents that cannot be sent through pipes made of traditional materials.

These Tees are used in various industries like chemical processing, gas and electricity generation, pharmaceuticals and many more. They are an essential part of the industrial process in multiple systems, which would otherwise be rendered useless without them!

PTFE Lined Reducing Tee Specifications

| Size | : | 25 NB to 300 NB |

| Hydro Test | : | at 29.8 Kg/cm2 |

| Flanges Connection | : | ANSI B 16.5 |

| Spark Test | : | 15 KVA |

| Outer Body | : | ASTM A 395 Gr 60-40-18 |

| Face to Face | : | ANSI B 16.10 |

| FEP- Max Temp | : | 180° C |

| PP Max Temp | : | 100° C |

| PFA Max Temp | : | 200° C |

Material of Construction

- Tee & Cross are supplied either in FEP OR PFA lined depending on process liquid handled & as per standard resin specification

- ASTM D 2116 & ASTM D 3307 Type II respectively

- ASTM-A-234, Grade WPB in compliance with ANSI-B-16.28

- Tee & Cross are being supplied with fixed flanges

Application

- SS 304 PTFE Lined Reducing Tee uses in Chemical Industry

- PTFE Lined Reducing Tees uses in Power Generation Plants

- PFA Lined Tees uses in Oil & Gas Industry

- MS PTFE Lined Pipe Tees uses in Petrochemical Refining Industry

- MS FEP Lined Reducing Tee uses in Paper & Pulp Industry

- MS PFA Lined Reducing Tee uses in Pharma Industry