A lined eccentric reducer is designed to reduce the pressure in a pipe by creating a seal between the pipe and the fitting. A lined eccentric reducer is often used in high-pressure applications, such as oil and gas pipelines, where the pressure inside the pipe can be very high. Lined eccentric reducers are also used in water and wastewater treatment systems, where the pressure inside the pipe can be very high.

Lined eccentrics are made from PTFE (polytetrafluoroethylene) or FEP (fluorinated ethylene propylene), synthetic rubber resistant to corrosion. The seal created between the pipe and fitting is created by lining the inside of the fitting with PTFE or FEP. The sealing material is then coated with PTFE or FEP, creating a tight seal between the pipe and the fitting.

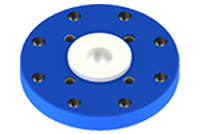

PTFE Lined Eccentric Reducer Specifications

| DECRIPTION | TECHINICAL DATA |

|---|---|

| Eccentric Reducer | ASTM A 234 grade WPB, ANSI B 16.9,Sch 40 upto 150 NB,Sch 30 upto 250 NB & Sch 20 for 300 NB. |

| Flanges | MS Plate Flanges As per IS2062, ASA 150# Both Fix |

| PTFE Liners / Lining | Isostatic Molded with Std. Resin as per ASTM D 1457 White, PFA Lined to ASTM D 3307 / OR FEP Lined to ASTM D 2116 or Equivalent |

| Testing & Inspection | Spark tested for 10 KV & Hydro tested at 10 kg/cm2 & painted with 2 coates of Red Oxide Primer |

| Pressure Rating | Vacuum to 6 kg/cm2 |

| Temp. Rating | (-)29 °C TO 260° C |